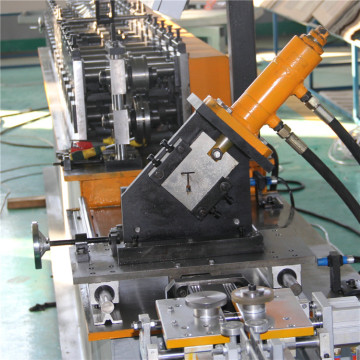

Main T Bar Gride Roll Forming Machine

Basic Info

Model No.: KTY

Product Description

Main T Bar Gride Keel Roll Forming Machine

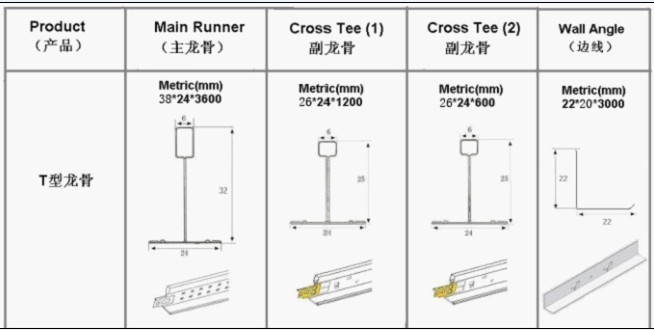

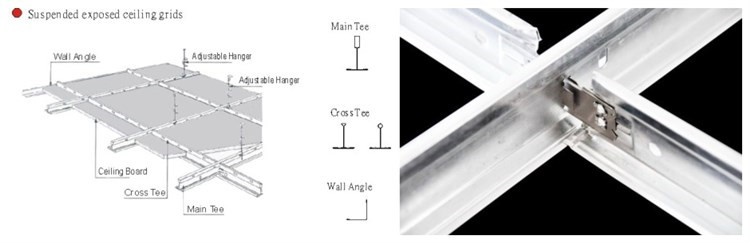

For the main T bar gride keel roll forming machine is usually used together with the croll T machine and the angle machine .

Main T: equiped with inverter motor, producing in line speed: 30M per minute. Hydraulic automatic punching and cutting machine linked with main forming machine,punching and cutting automatically. Two heads and middle holes are punched and cut-off at the same time after forming.

Cross T: equiped with both inverter and servo motor producing in line speed: 30M per minute. Main machine with constant speed,it is traced by the servo trace system, automatic tracing the speed of the main machine, punching and cutting automatically. Two heads and middle hole are punched and cut-off at the same time after forming.

What is the detailed component of the Main T bar roll forming machine ?

Decoiler

Usage: It is used to support the steel coil and uncoil it in a turntable way. Passive uncoil pulled by roll forming system

Loading capacity: 3T

Uncoiling width: 500mm

Inner diameter: 450-550mm

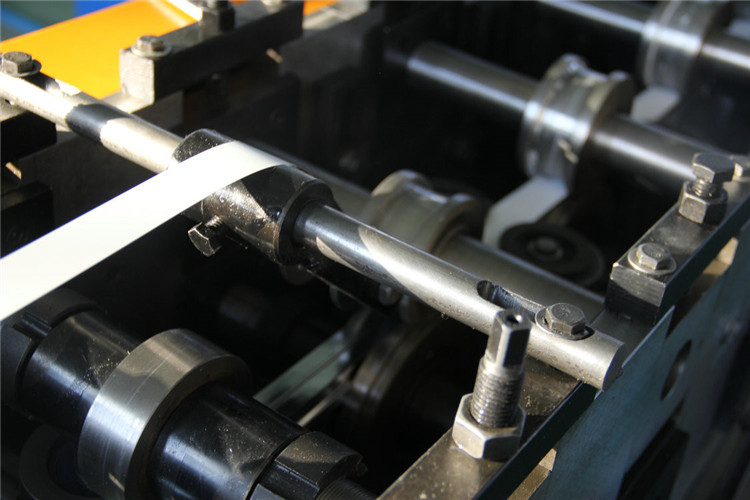

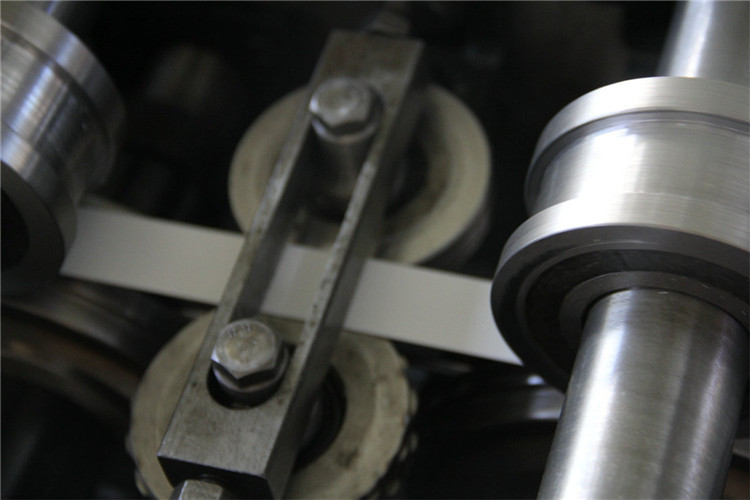

Main roll forming machine:

Feeding and flatting will make sure the steel is neat clean and straight.

Roller fixer : Guide column

Frame : middle plate welded Memorial arch frame type

Drive mode: gear

Diameter of shafts: φ40mm

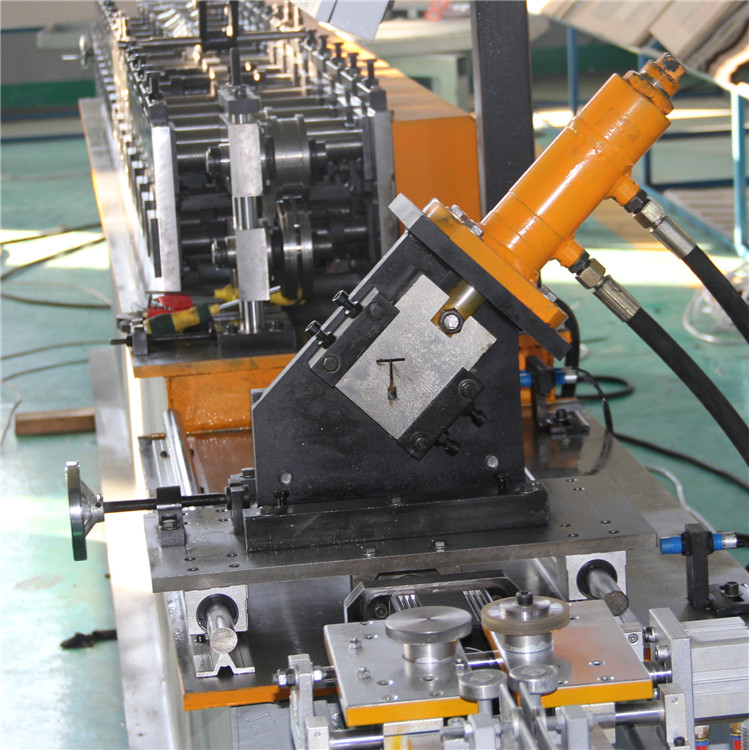

Shearing machine:

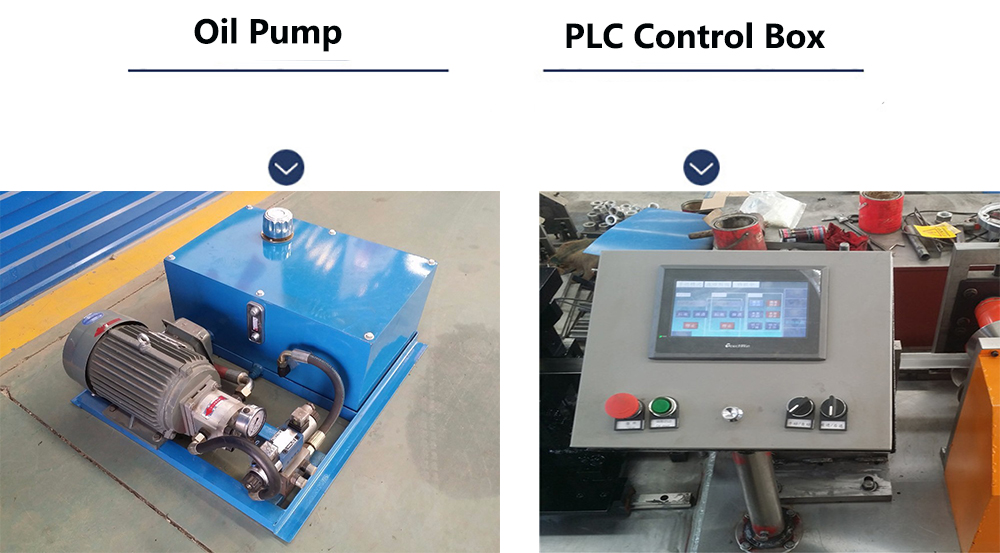

Power supply : hydraulic power

Frame : Pillar style with rack & pinion system

Stroke switch : non-contact photoelectric switch

Electic Control System:

1. Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

2.Other electric element are Delta

3. Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety.

What is the advantage of the stud and track roll forming machine ?

- Fully automatic . The machine is total automatic , just need to set the data on the touch screen , then it can work automaticly . it just need two worker to operate .

- No-stop cutting system . The cutting system of the machine is hydraulic tracking cutting , it can highly imporve your productivity .

- Multi-size. The machine can produce several size , we can change the size by adjusting the spacer .

How it benefit the client from the advantage ?

-

Save labor cost . As the machine is fully automatic , it just need two workers to operate . Surely it can save labor cost .

-

Improve your productivity . the machine is no stop cutting system , its speed can reach 60 meter per minute so it can highly imporve your productivity . It can help you get more order and them imporve your profit .

-

Save space and cost . This machine can produce several size panel , so it save your space and cost .

What is the application of the stud and track roll forming machine?

Because products has smooth appearance beautiful appearances, uniform lacquer veins, high strength, durable, widely used in decorating the ceiling and wall for industrial and civil buildings, such as workshop, warehouse, locomotive shed, hangar room, gymnasium, exhibition halls, theaters and other surface and wall .

What is the parameter of the stud and track roll forming machine ?

| Stud and track roll forming machine | ||

| Raw Material | raw material | Galvanizes strip |

| Thickness of raw material | 0.3-0.8mm | |

| Main machine | Main motor power | 7.5 kw |

| Forming Steps | 12 steps | |

| Shaft material | 45# quenched | |

| Shaft diameter | 50mm | |

| Roller mateiral | 45# hard chromed plated | |

| Transmission | gear wheel | |

| Forming speed | 50-60 meter/min | |

| Cutting system | Cutting | Hydraulic tracking cutting |

| Blade material | Cr12 | |

| Pump power | 4kw | |

| PLC | PLC | Panasonic |

Our factory is specialized in producing all kinds of roll forming machines. There are many professional engineers and workers to design and produce according to your need.

The machines produced by our factory has been sold worldwide such as Russia , Kazakhstan, England, America, Italy, Australia, Philippines, India, Thailand, Nigeria and Syria, etc. So we are with great facility about the different needs for different markets.

I'm working for this factory since 2011 and thanks for my people guiding me and help me at the beginning. With the years of experience, I know how to deal the business in a right way and give the customer friend the better service. My advantage is that I'm patient for each client, seriously for each detail on business. I wish we can get the bigger win-win profits based on our cooperation.

Product Categories : Stud And Track Roll Forming Machine > T Bar Roll Forming Machine