Steel Structure Chicken Farm House for modern Farm

Basic Info

Model No.: steel -1

Product Description

Model NO.: steel -1 Usage: Warehouse, Villa, Workshop, Farm House Customized: Customized Beam Distance: 3 Meters Wall and Roof: Sandwich Panel or Steel Plate + Fiberglass Door: Roolingdoor or Siliding Door Payment: 50% Depoist Shipping Port: Qingdao ,China Specification: ISO9001 HS Code: 9406000090 Material: Steel Structure Certification: ISO, SGS Steel Beam Material: Hot Gavalnized C Steel or H Section Steel Appication Life: 50 Years Purlin: C/Z-Hot Gavalnized Steel Delivery Time: 20 Days After Receiving Deposit or L/C Installation on Site: Yes Trademark: SuperHerdsman Origin: China General Description for chicken house design

1) Generally the height of poultry houses is between 2.5m-3.5m (at eaves). The width of the poultry houses is decided according to then layout of equipment inside and cannot be too large considering ventilation. Steel structure poultry houses are usually designed with the width of 8-15m. Length is better no larger than 150m.

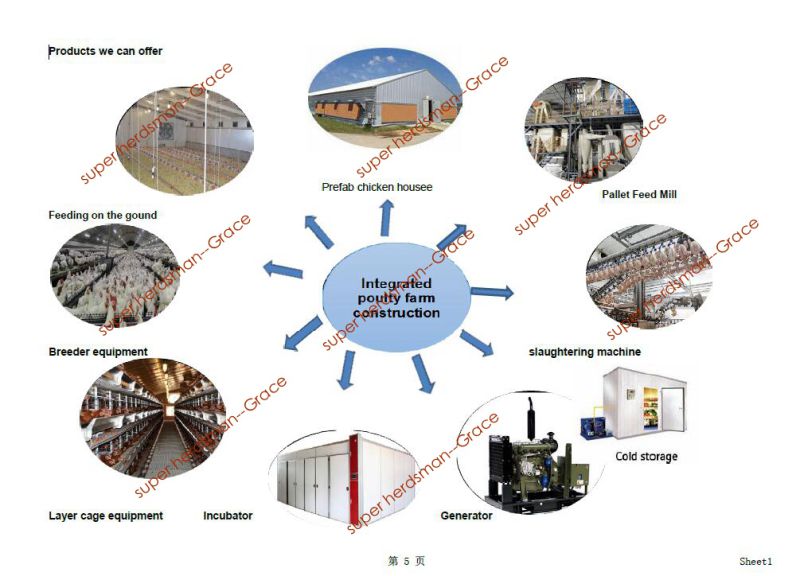

2) In modern chicken farms, chicken feeding is operated in large scale in an automatic way. A complete set of equipment in a poultry house consists of the following items: automatic feeding system, automatic Nipple Drinking System, exhaust fan, evaporative Cooling Pad, floor for dung leakage, etc..

.Main components of steel structure chicken hosue

.Environment control of poultry house

Cooling pad system

Evaporative cooling pad system works in the condition of negative pressure, the cooling pad is installed on one side of the wall, fan installed other side. When air flow through cooling pads, the water evaporation absorbs a lot amount of heat.

The height of cooling pad is 1.5-2.2m, the area of cooling pad in chicken house is about 6-8 times than the fans.

ventilating system

The main parts of ventilation system is the big fan and small fan. They are controlled by the control system. The NO. of the fans to run was decided by the temperature of the poultry house.

About 200m2 need 1 big fan and 15-20m need a small fan, this is the standard to design the quantity of fans in chicken house.

.Advantages for steel structure house

1) Easy to assemble and disassemble with simple and common tools.

2) Heat and sound insulation, water and fire proofing.

3) Attractive appearance

4) Environmentally friendly and economical . Reasonable design makes it reusable. The reusable character makes it environmentally friendly and economical.

5) Cost efficient -- A grade materials, reasonable price, all investment low requirements for base and short completion time make it cost efficient.

6) Light weight, convenient for shipment and transportation of the steel structure warehouse construction.

7) the components of the house can be used repeatedly

Breeding equipment

Automatic pan feeding line system

Automatic nipple drinking line system

This system can provide fresh and clean water for poultry which is crucial for the growth of Poultry.

The drinkers can be triggered from 360 degree which helps young birds start well and makes drinking easier.

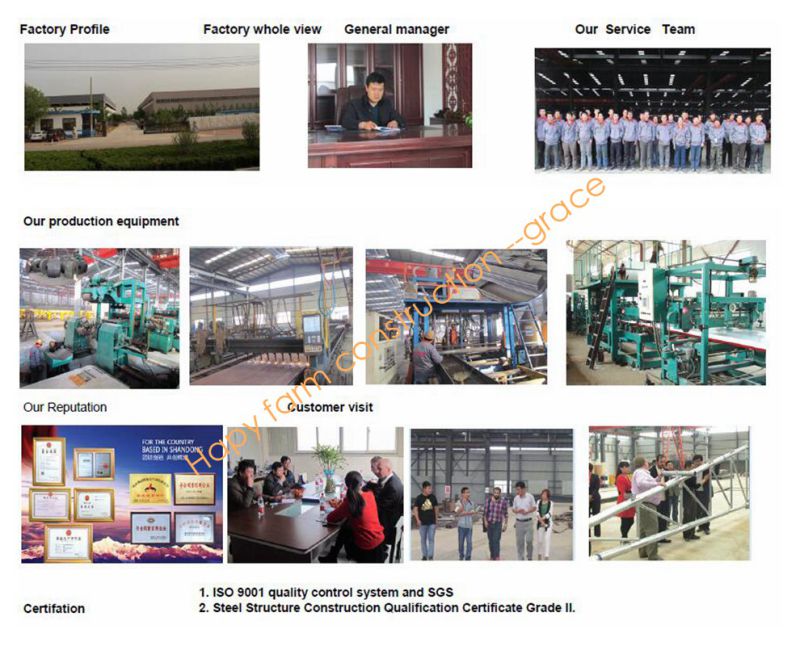

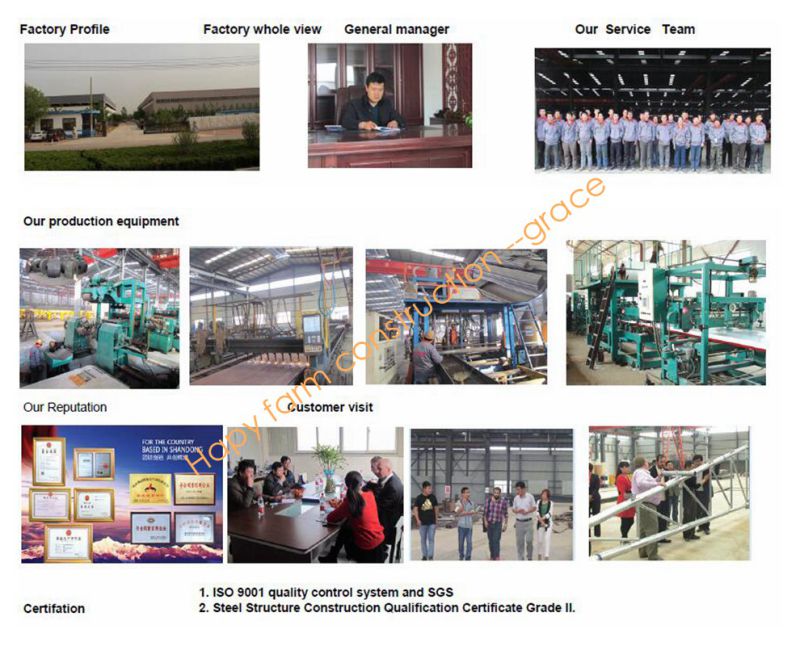

VI.Certification :

1. Iso 9001 quality control system .

2. Steel Structure Construction Qualification Certificate Grade II.

VII. Our factory :

About US

1. Professional steel structure manufacturers since 2003.

2. Professional poultry equipment manufacturers since 2009

3. 2, 0000 sqare meters workshop for steel structure

VIII .Excellent service we can offer :

1. Poultry house site selection;

2. Poultry house design and construction;

3. Poultry equipment installation;

4. breeding trainning for operation workers

Contact us if you need more details on Chicken Farm. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Steel Structure、Chicken Farm House. If these products fail to match your need, please contact us and we would like to provide relevant information.

1) Generally the height of poultry houses is between 2.5m-3.5m (at eaves). The width of the poultry houses is decided according to then layout of equipment inside and cannot be too large considering ventilation. Steel structure poultry houses are usually designed with the width of 8-15m. Length is better no larger than 150m.

2) In modern chicken farms, chicken feeding is operated in large scale in an automatic way. A complete set of equipment in a poultry house consists of the following items: automatic feeding system, automatic Nipple Drinking System, exhaust fan, evaporative Cooling Pad, floor for dung leakage, etc..

.Main components of steel structure chicken hosue

| 1. Base: | Concrete and steel foundation bolts |

| 2. Column and beam: | material Q345(S355JR)or Q235(S235JR) steel, all bolts connection ,straight cross-section or Variable cross-section |

| 3. Bracing: | X or V or other type bracing made from angle , round pipe etc. |

| 4. Galvanized C or Z purlin: | size from C100~C320,Z160~Z300 |

| 5. Roof and Wall Panel: | 1.Single colorful corrugated steel sheet --Thickness:0.12-1.2mm; Width: 310-1150mm, etc. 2.Sandwich panel with EPS, rock wool, glass wool , PU etc. insulation -- Thickness around 50mm~150mm; Width : 970mm or 950mm |

| 6. Vertical and transversal support: | Q235 angle steel, round bar or steel pipe. |

| 7. wall | Wire meshes with curtain system or sandwich panel |

| 8. equipment | 1.Main feed line system 2.Pan Feeding System 3.Nipple drinking system 4.Ventilation system 5.Cooling pad system 6.Spraying System 7.Heating system 8.Environment Control System |

| 9. life span | 50 years |

| 10 packing | Standard container package 40 GP or 40 HQ container |

| 11. size | Customized |

| 13. Installation on site | Available |

.Environment control of poultry house

Cooling pad system

Evaporative cooling pad system works in the condition of negative pressure, the cooling pad is installed on one side of the wall, fan installed other side. When air flow through cooling pads, the water evaporation absorbs a lot amount of heat.

The height of cooling pad is 1.5-2.2m, the area of cooling pad in chicken house is about 6-8 times than the fans.

ventilating system

The main parts of ventilation system is the big fan and small fan. They are controlled by the control system. The NO. of the fans to run was decided by the temperature of the poultry house.

About 200m2 need 1 big fan and 15-20m need a small fan, this is the standard to design the quantity of fans in chicken house.

.Advantages for steel structure house

1) Easy to assemble and disassemble with simple and common tools.

2) Heat and sound insulation, water and fire proofing.

3) Attractive appearance

4) Environmentally friendly and economical . Reasonable design makes it reusable. The reusable character makes it environmentally friendly and economical.

5) Cost efficient -- A grade materials, reasonable price, all investment low requirements for base and short completion time make it cost efficient.

6) Light weight, convenient for shipment and transportation of the steel structure warehouse construction.

7) the components of the house can be used repeatedly

Breeding equipment

Automatic pan feeding line system

| V-shape bin (with hopper) | Bin volume: 100L Material: hot-dip galvanized sheet |

| Motor | Taiwan brand Power: 0.75Kw/1.1Kw/1.5Kw Voltage: 380V, three-phase/220V, single-phase/others |

| Delivery pipe | Diameter of pipe: 45mm Material: hot-dip galvanized steel |

| Auger | Origin: South Africa Feeding ability: 450Kg/h (maximum) |

| Feed pan | Pan distance: 4 pans/3m, 3 pans/3m Raising ability: 45-55 birds/pc Material: pure engineering plastic |

| Sensor | Origin: Germany |

| Suspension &lifting device | We can adjust the feeding line by winch. |

| Anti-perching device | It prevents birds staying on the feeding line for too long. |

Automatic nipple drinking line system

This system can provide fresh and clean water for poultry which is crucial for the growth of Poultry.

The drinkers can be triggered from 360 degree which helps young birds start well and makes drinking easier.

VI.Certification :

1. Iso 9001 quality control system .

2. Steel Structure Construction Qualification Certificate Grade II.

VII. Our factory :

About US

1. Professional steel structure manufacturers since 2003.

2. Professional poultry equipment manufacturers since 2009

3. 2, 0000 sqare meters workshop for steel structure

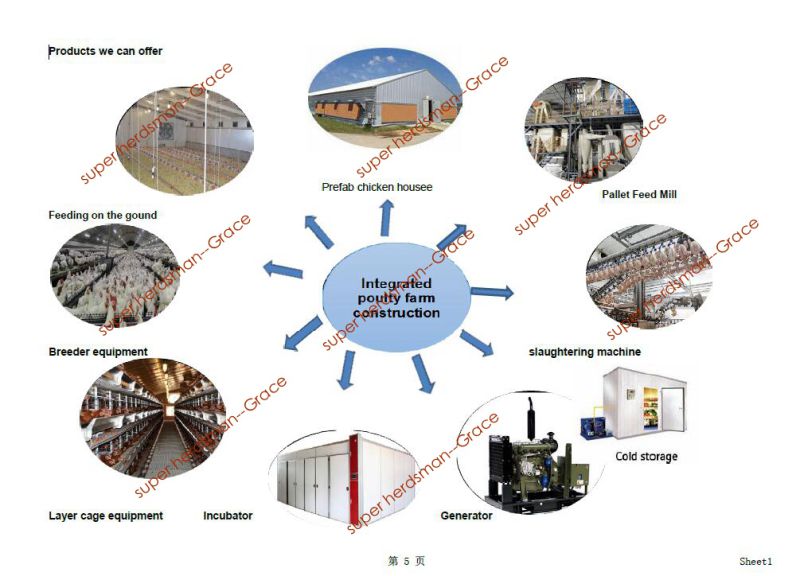

VIII .Excellent service we can offer :

1. Poultry house site selection;

2. Poultry house design and construction;

3. Poultry equipment installation;

4. breeding trainning for operation workers

Contact us if you need more details on Chicken Farm. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Steel Structure、Chicken Farm House. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Poultry Farm Construction

Premium Related Products

Other Products

Hot Products

Automatic Egg Incubator for ChikenPanel Door for Poultry HousePoultry Equipment Chicken Nipple Drinker with DoserAutomatic Poultry Equipment for Breeder ManagementAxial Fans Used in Poultry FarmingEvaperative Air Cooler Poultry EquipmentHigh Quality Chicken House Poultry Slat and SupportPoultry Equipment with Poultry Light TrapFull Set Automatic Poultry Farming EquipmentsAutomatic Poultry Equipment for Breeder HouseHigh Quality Poultry Feeders and Drinkers for DuckManual Laying Nest for Breeder FarmPoultry Farming Equipment for Chicken Shed Air CoolerWinch Used in Poulty EquipmentFull Set High Quality Automatic Poultry Equipment for BroilerPoultry Farm Water Drinking System (shn001)