Automatic Layer Chicken Farm Equipment with SGS Certification

Basic Info

Model No.: shc-332

Product Description

Model NO.: shc-332 Usage: Chicken Breeding Euqipment Power Source: Electric Epidemic Prevention Equipment: Mobile Vaccination Car Certification: SGS, ISO9001:2008 Frame Type: H Shaped Delivery Time: 20 Days After Deposite Cage Size: 2250*600*430 Cage Feed Capacity: 16~24 Birds~/Cage Cells of Cage: 5 Cells Specification: ISO9001 HS Code: 84362900 Type: Chicken Farming Equipment Application: Chicken Heating and Ventilation Equipment Type: Steam or Hot Water Heating Computerized: Computerized Condition: New Installation on Site: Availabel Brand Name: Super Herdsman Group Type: H Type Frame Delivery Port: Qingdao, China Trademark: superherdsman Origin: Shandong, China (Mainland) Automatic poultry cage farm for broiler and layers

I.General description

Our poultry cage equipment for layer chicken Complete have achieved automatic control of feeding system ,ventilation system egg collection system, drinking system,manure remove system;the products have the advantages of simple structure,steady performance, feeding equipment, energy and workload saving ,durability and reliability etc.

II.Components of Equipment

1. Auto Feeding system

Automatic feeding, saving manpowet,improve labor productivity

2.360°Nipple Drinking System

Adopting advanced nipple automatic drinking system with no leakage to keep the poultry house dry, and to reduce the risk of disease infection.

3.egg collection machine

1)complete Auto Egg Elevator Sys., with outegg handling platform with belt calmb

2)egg cross collection system

3)Egg Belt, nylon material ,95mm wide Zero damage rate

4.chicken cage manure removal system

Belt manure removal system makes manure drier and easier to to remove and recycle,and heighten the efficiency of reusing manure. transport the manure directly to the vehicle outside the house.

5.Automatic ventilation system

This system controls climate conditions,fresh air,humidity and temperature in poultry shed.

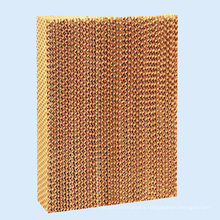

6. Cooling Pad system

Cooling pad and fanis the most economic and effective summer cooling system for poultry house.

7.Environment Control System

This system saves labor and the resources under the condition of assuring the optimum growth environment of poultry chickens.

8.Heater

Heating poultry house when it is needed to satisfy the temperature demand of chickens at different growth stage .

III.Advantages

1. automatic feeding, saving manpowet,improve labor productivity

2. special and flexibel design for cage side

3. beneficial design for chicken healthy growth to increase the meat

4. rational structure to decrease the dosage for chicken

5. free chicken house design and technology support

6. improve the survival rate of chicken because the rational cage

VI. Detail information for cage equipment

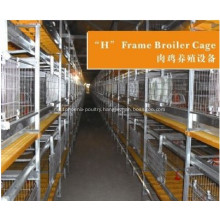

"H" type specifecations

"A " type specifications

V .Main components of steel structure chicken hosue

VI.Certification :

1. Iso 9001 quality control system .

2. Steel Structure Construction Qualification Certificate Grade II.

VII. Our factory :

1. Professional steel structure manufacturers since 2003.

2. Professional poultry equipment manufacturers since 2009

3. 2, 0000 sqare meters workshop for steel structure

VIII .Excellent service we can offer :

1. Poultry house site selection;

2.Light steel structure Poultry house design and construction;

3. Poultry equipment installation and test ;

4. Breeding trainning for operation workers

Contact us if you need more details on Layer Chicken Farm. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Farm Machinery、Chicken Layer Cage. If these products fail to match your need, please contact us and we would like to provide relevant information.

I.General description

Our poultry cage equipment for layer chicken Complete have achieved automatic control of feeding system ,ventilation system egg collection system, drinking system,manure remove system;the products have the advantages of simple structure,steady performance, feeding equipment, energy and workload saving ,durability and reliability etc.

II.Components of Equipment

1. Auto Feeding system

Automatic feeding, saving manpowet,improve labor productivity

2.360°Nipple Drinking System

Adopting advanced nipple automatic drinking system with no leakage to keep the poultry house dry, and to reduce the risk of disease infection.

3.egg collection machine

1)complete Auto Egg Elevator Sys., with outegg handling platform with belt calmb

2)egg cross collection system

3)Egg Belt, nylon material ,95mm wide Zero damage rate

4.chicken cage manure removal system

Belt manure removal system makes manure drier and easier to to remove and recycle,and heighten the efficiency of reusing manure. transport the manure directly to the vehicle outside the house.

5.Automatic ventilation system

This system controls climate conditions,fresh air,humidity and temperature in poultry shed.

6. Cooling Pad system

Cooling pad and fanis the most economic and effective summer cooling system for poultry house.

7.Environment Control System

This system saves labor and the resources under the condition of assuring the optimum growth environment of poultry chickens.

8.Heater

Heating poultry house when it is needed to satisfy the temperature demand of chickens at different growth stage .

III.Advantages

1. automatic feeding, saving manpowet,improve labor productivity

2. special and flexibel design for cage side

3. beneficial design for chicken healthy growth to increase the meat

4. rational structure to decrease the dosage for chicken

5. free chicken house design and technology support

6. improve the survival rate of chicken because the rational cage

VI. Detail information for cage equipment

"H" type specifecations

| Item No. | Cell Length | Cell Depth | Cell Height | Unit Dimension | Cells/Unit/Set | Tiers/ Set | Birds/cell/ unit/set |

| HY-A390 | 390 | 350 | 380 | 1950*350*380 | 5/6 | 3 | 3/15/90 |

| HY-A4120 | 390 | 350 | 380 | 1950*350*380 | 5/8 | 4 | 3/15/120 |

| HY-A396 | 490 | 350 | 380 | 1960*350*380 | 4/6 | 3 | 4/16/96 |

| HY-A4128 | 490 | 350 | 380 | 1960*350*380 | 4/8 | 4 | 4/16/128 |

| HY-A3120 | 430 | 420 | 410 | 2150*420*410 | 5/6 | 3 | 4/20/120 |

| HY-A4160 | 430 | 420 | 410 | 2150*420*410 | 5/8 | 4 | 4/20/160 |

"A " type specifications

| Battery cage for layer with feeding & drinking fittings | |||

| Type | Tier | Whole size ( L by W by H ) | Bird capacity As different age |

| Cage feeding | A type, 2 tiers | 1.85M by 1.8M by 1M | 12 cells, 8birds per cell,Total 96birds |

| A type,3 tiers | 1.85M by 2.2M by 1.5M | 18cells, 8birds per cel l Total 144birdsl, | |

| A type,4tiers | 1.85M by 2.8M by 3M | 24cells, 8birds per cell,Total 192birds | |

| H type,3tiers | 2400*1600*2130mm | 3Cells, 72birds per cell,Total 216birds | |

| H type,4tiers | 2400*1600*2720mm | 4Cells, 72birds per cell,Total 288birds | |

V .Main components of steel structure chicken hosue

| 1. Base: | Concrete and steel foundation bolts |

| 2. Column and beam: | material Q345(S355JR)or Q235(S235JR) steel, all bolts connection ,straight cross-section or Variable cross-section |

| 3. Bracing: | X or V or other type bracing made from angle , round pipe etc. |

| 4. Galvanized C or Z purlin: | size from C100~C320,Z160~Z300 |

| 5. Roof and Wall Panel: | 1.Single colorful corrugated steel sheet --Thickness:0.12-1.2mm; Width: 310-1150mm, etc. 2.Sandwich panel with EPS, rock wool, glass wool , PU etc. insulation -- Thickness around 50mm~150mm; Width : 970mm or 950mm |

| 6. Vertical and transversal support: | Q235 angle steel, round bar or steel pipe. |

| 7. wall | Wire meshes with curtain system or sandwich panel |

VI.Certification :

1. Iso 9001 quality control system .

2. Steel Structure Construction Qualification Certificate Grade II.

VII. Our factory :

1. Professional steel structure manufacturers since 2003.

2. Professional poultry equipment manufacturers since 2009

3. 2, 0000 sqare meters workshop for steel structure

VIII .Excellent service we can offer :

1. Poultry house site selection;

2.Light steel structure Poultry house design and construction;

3. Poultry equipment installation and test ;

4. Breeding trainning for operation workers

Contact us if you need more details on Layer Chicken Farm. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Farm Machinery、Chicken Layer Cage. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Cage System

Premium Related Products

Other Products

Hot Products

Automatic Egg Incubator for ChikenPanel Door for Poultry HousePoultry Equipment Chicken Nipple Drinker with DoserAutomatic Poultry Equipment for Breeder ManagementAxial Fans Used in Poultry FarmingEvaperative Air Cooler Poultry EquipmentHigh Quality Chicken House Poultry Slat and SupportPoultry Equipment with Poultry Light TrapFull Set Automatic Poultry Farming EquipmentsAutomatic Poultry Equipment for Breeder HouseHigh Quality Poultry Feeders and Drinkers for DuckManual Laying Nest for Breeder FarmPoultry Farming Equipment for Chicken Shed Air CoolerWinch Used in Poulty EquipmentFull Set High Quality Automatic Poultry Equipment for BroilerPoultry Farm Water Drinking System (shn001)