Full Set Environment Controlled Chicken Shed Machinery for Broiler

Basic Info

Model No.: SHF-0032

Product Description

Model NO.: SHF-0032

Usage: Broiler Procuction

Power Source: Electric

Epidemic Prevention Equipment: Mobile Disinfecting Car

Certification: SGS, ISO9001:2008

Brand Name: Superherdsman

Payment: T/T 30% Deposit or L/C at Sight

Feed Pan Capacity: 40-55birds/Pan

Feed Delivery Pipe Spec.: 3 Meters /Unit with 4 Pans

Trademark: superherdsman

Specification: ISO9001

HS Code: 84362900

Type: Poultry Farm Equipment

Application: Chicken

Heating and Ventilation Equipment Type: Hot Blast Stove

Computerized: Computerized

Condition: New

Delivery Time: 20days After Receive Your Your Deposit or L/C

Delivery Port: Qingdao ,China

Nipple Capacity: 8-12 Birds/Nipple

Water Line Tube Spec.: 4 Meters /Unit with 16 Nipples

Transport Package: Standard Export Package

Origin: China

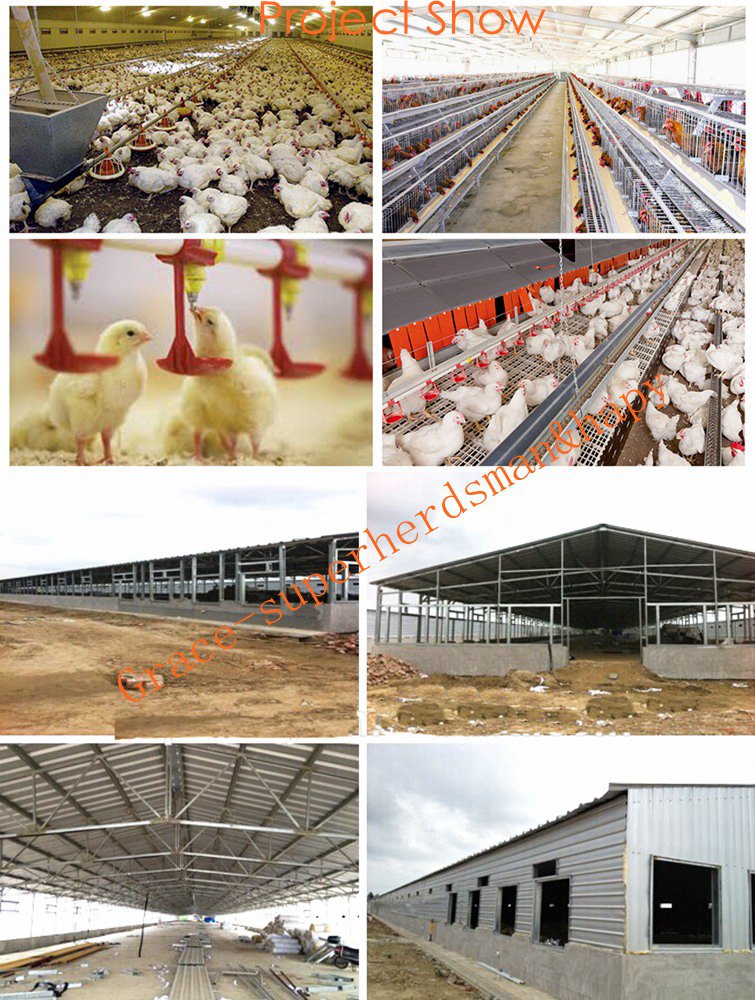

Full set Automatic poultry equipment for broiler production

Our automatic broiler production system includes 9 parts :

1. Main Feeding System

2. Broiler pan feed system

3. Nipple Drinking System

4. Ventilation system

5. Environment Control System

6. Cooling Pad system

7. Spraying System

8. curtain system

9 heating system (heater )

1.Automatic main feeding system

a. The main feeding system consists of steel silo ( or big hopper ) driving system ,feed pipe ,auger .

| Silo /manpower hopper | 1. silo/manpower hopper is the beginning of main feed line 2. material : hot galvanized zinc steel sheet ( coating thickness: more than 275g/m2 |

| Driving motor | 075kw or 1.1kw , 220v 50hz , three phases |

| Delivery pipe | 1.material : pvc tube 2. diameter: 75mm*3.6mm 1400 kg /hour max distance : 60meters 90mm*4.0mm 2500kg/hour max distance : 40meters |

| Auger | Imported from south afric |

| Usage | The main feeding system is used to transfer the feed from silo to sub-hoppers in house . |

| Function | There is a feed sensor at the end of the main delivery line , which control of open and close of the motor to realized the automatic feeding . |

2.Automatic Pan Feeding System

Automatic pan feeding system consists of driving motor, hopper, delivery pipe, auger ,feed pan , hanging and lifting device , anti-roost system , and fee sensor .

| Hopper | a. Hopper volume: 100L b.Material: hot-dip galvanized sheet |

| Driving motor | a. Taiwan brand Power: 0.75Kw/1.1Kw/1.5Kw b. Voltage: 380V, three-phase/220V, single-phase/three phase |

| Delivery pipe | a. Diameter of pipe: 45mm b. Material: hot-dip galvanized steel |

| Auger | a. Imported from south Africa Feeding ability:450kg/h b. Maximum conveying length:140m |

| Feed pan | a. Material : PP Diameter:360mm×360mm b. Pan distance: 4 pans/3 meters, 3 pans/3 meters |

| Hanging and lifting device | Driven by winch to adjust the height of the whole feeding line through pushing or pulling the steel wire according to the chicken day's age. |

| Anti-roost system | prevents birds staying on the feeding line for too long. |

| Feed senor | Imported from Germany; time delay range 0 to 2 hours. |

3.Automatic nipple drinking system

Nipple drinking system composed of water front parts ,drinking system ,hanging system ,regulator ,water end parts .

| Water front parts | 1. Including filter , water meter ,and dose . 2. Function : adjust water supply and stabilize drinking volume ,dose medicine , wash sediment |

| Water pipe and nipple drinkers and drip cup | 1. Water pipe : transparent PVC material 2. Nipple drinker: a. double-sealing structure, good seal performance and never leak water b. Chicken could freely drink from 360 degree. c. outer engineering plastic and inner stainless steel 3.drip cup :single-arm drip cup with a reasonable structure |

| Regulator and indicating tube | 1. Regulator :stable running , high dexterity , sufficient and even liquidity . 2. Transparent indicating tube to observe the water level Poultry Days Water Level Height(mm) 1~ 7 days 50~80mm 8~14 days 80~200mm ≥ 15 days 200~350mm |

| Hanging system | Eeasy to adjust height of this drinking system in different poultry growth. It is very important to keep a right and appropriate height for poultry in different growth period |

| Seamless G.I. Water Line Supporting Pipe | more rust-resistant and longer service life compared with welded pipe |

feeding capacity

broile:8-12 birds/nipple

birds in cage:12 birds/nipple

turkey:20 birds/nipple

duck:10 birds/nipple

Breeder 10 birds/nipple

4. Ventilation system

a. The system controls climate condition, can provide fresh air, proper humidity and temperature for birds, ensuring your chickens provide maximum production

The system including ventilation fan (box fan or butterfly cone fan) and air inlets.

2. If your chicken farm is open, there is no need to use 36'' fan and air inlets, however, you might need curtain system.

| Specifications | 50'' box fan | 36'' box fan |

| Flow amount (m3/h) | 41000 | 20800 |

| Size (L*W*H) (mm) | 1380*1380*450 | 1000*1000*450 |

| Noise level | ≤65DB | ≤64DB |

| Power | 1.1Kw | 0.4Kw |

| Voltage | 380V/220V/others | 380V/220V/others |

| Current | 2.8A | 1.6A |

| Weight | 88Kg | 66Kg |

5.Cooling pad

A. When the air goes through the pad, the heat will be took down by the evaporation of water, so the air will be cooled before going into the chicken farm.

B. The cooling pad and the ventilation fan combination is the most economical and effective to decrease the temperature in summer

C. Reasonably design and installed the cooling pads can control the temperature in the poultry house to 30 degree centigrade or under hottest feature

| Thickness | 100mm, 150mm |

| Width | 300mm, 600mm |

| Height | 1660mm, 1960mm, 2160mm (with frame) 1500mm, 1800mm, 2000mm(without frame) |

| Frame | Aluminium alloy frame --high strength, good corrosion resistance, even water distribution, compact structure, beautiful and practical. Galvanized steel frame for your option, lower price than aluminium alloy frame. |

6. Environment control system

A.The system saves labor and resources under the condition of assuring the optimum growth environment of chickens.

B.It is imported from Israel can set an optimum working mode according to the local climate and raising environment.

7. Spraying and disinfecting system

It's effective tool for cooling, damping, dedusting and disinfecting the house.(the temperature is quickly reduced by 3-8 degrees centigrade within a few minutes)

8. Heating system(heater):

*Proper temperature is critical to chickens, especially day-old chicks, we have different kinds, they fire coal, diesel, gas or use electricity, 4 kinds for your option.

9.Curtain system:

In some tropical zone, the farmers are inclined to use curtain instead of real walls(open farm),they will not use big fan accordingly.

Our curtain have two kinds for your choice, manual operated one and motorized one.

| (1)What information you are supposed to provide to get a good price? |

| a. Chicken farm size (Length*width*height); |

| b. Quantity of chickens in one farm; |

| c. Weight of chickens when they're for sale in market; |

| d. Types of chicken: broiler/breeder/layer (WE ALL HAVE); |

| e. Types of breeding: on the ground/in cages; |

| f. Chicken farm location and local climate condition (temperature, humidity...); |

| g. More information you think helpful. |

ABOUT US

Qingdao Hapy Poultry & Livestock Farm Construction Co., Ltd. , is the professional poultry farm equipment manufacturer with more than 10 years experience in poultry&livestock product development, project designing, installation, the poultry equipment have been sold under the brand "superherdsman" in more than 30 countries .

.Warranty

1. all the plastic products such as the feed pan ,water drip cup , clips ,water pipes and air inlet and so on all are made of Virgn PP .

the warranty time is 15 years

2. nipple: never leak , warranty time 15 years

3. the accessories such as the bolts and nuts and pulley , steel rope clips are made of stainless steel

4. motor : from Italy Transtechno.

5. Auger: from South Africa

6. Feed sensor : From Germany

Common FAQ for our poultry equipment quotation

1. What information you are supposed to provide to get a good price?

a. Chicken farm size (Length*width*height);

b. Quantity of chickens in one farm;

c. Weight of chickens when they're for sale in market;

d. Chicken farm location and local climate condition (temperature, humidity...);

2. payment details:

we can accept T.T ,30% Down payment and the balance Paid by T/T OR L/C before Shipment

3. Delivery time :

20days after deposite

4. what service we can offer :

a.Poultry house design and construction

b.Equipemnt production and installation on site

c.Offer Turn-key farm project construction

Contact us if you need more details on Poultry Control Shed Equipment. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Poultry Farm Machinery、Broiler Farm. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Main Feeding System

Premium Related Products

Other Products

Hot Products

Automatic Egg Incubator for ChikenPanel Door for Poultry HousePoultry Equipment Chicken Nipple Drinker with DoserAutomatic Poultry Equipment for Breeder ManagementAxial Fans Used in Poultry FarmingEvaperative Air Cooler Poultry EquipmentHigh Quality Chicken House Poultry Slat and SupportPoultry Equipment with Poultry Light TrapFull Set Automatic Poultry Farming EquipmentsAutomatic Poultry Equipment for Breeder HouseHigh Quality Poultry Feeders and Drinkers for DuckManual Laying Nest for Breeder FarmPoultry Farming Equipment for Chicken Shed Air CoolerWinch Used in Poulty EquipmentFull Set High Quality Automatic Poultry Equipment for BroilerPoultry Farm Water Drinking System (shn001)